Email Us

Ways to extend the life of milling cutters for insulating materials

Insulating materials such as epoxy resin, glass fiber reinforced plastic (GFRP), polytetrafluoroethylene (PTFE), etc. are widely used in the electronics, electrical, and aerospace industries. These materials usually have high hardness, strong abrasion resistance and low thermal conductivity, and the machining process requires very high requirements for cutting tools. If the insulating material milling cutter is not reasonably maintained and operated during use, it will often suffer from fast wear, reduced machining accuracy and even breakage. Therefore, to extend the service life of insulation material milling cutter, not only can significantly reduce production costs, but also improve the processing efficiency and product quality. So do you know what methods to extend the life of insulation material milling cutter? The following follow the Zhongye Da editorial to take a look at it!

Extend the life of insulation material milling cutter methods are as follows:

First, a reasonable choice of milling cutter material and coating

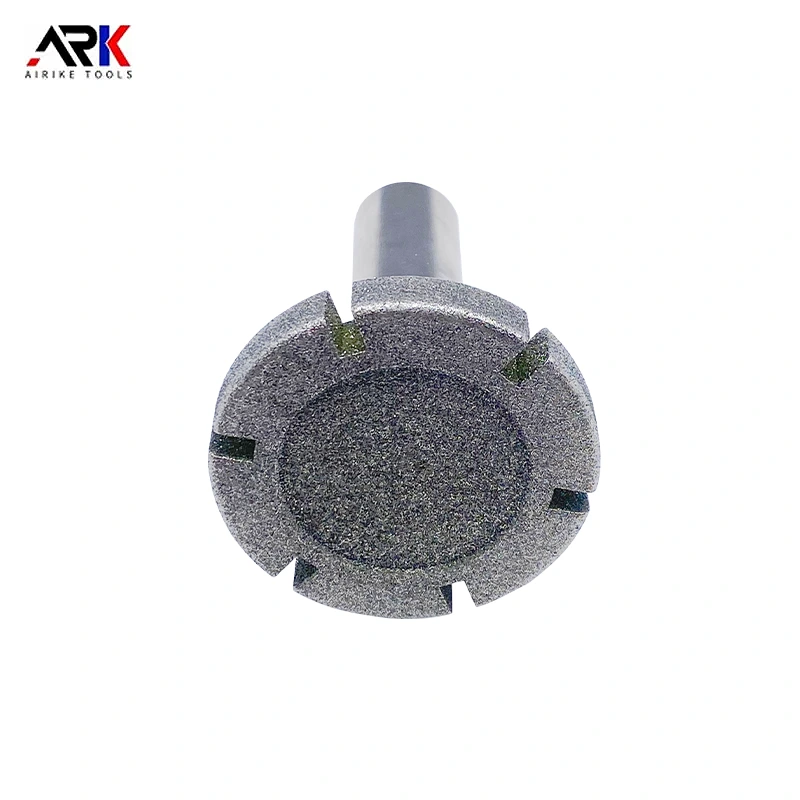

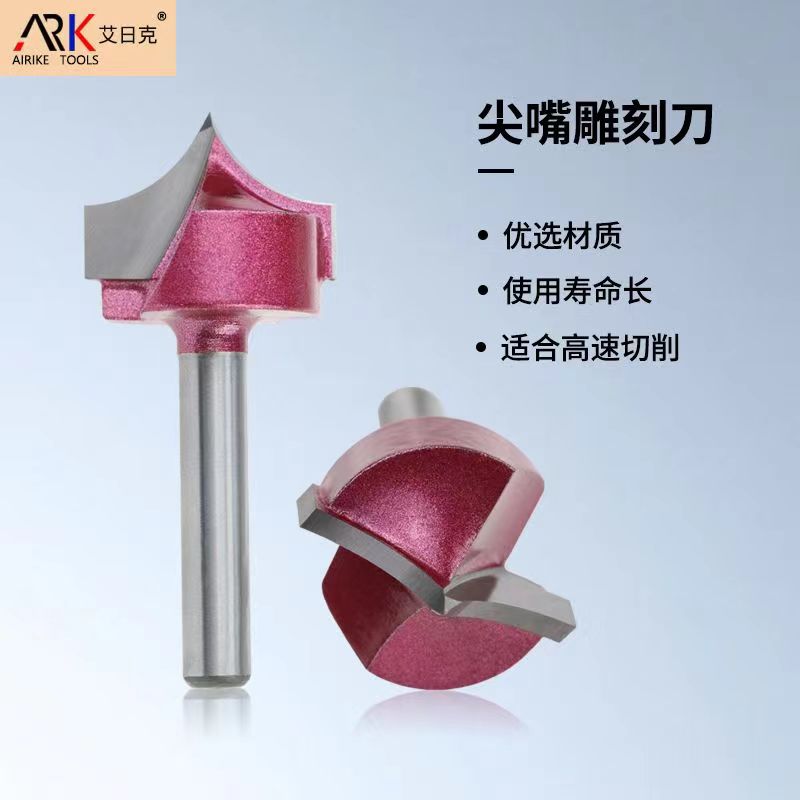

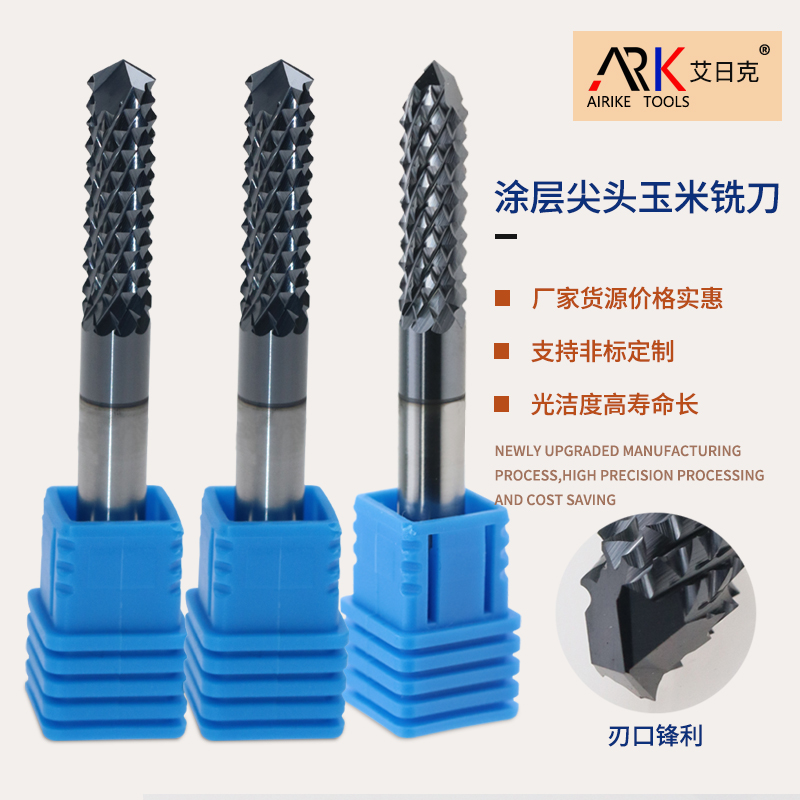

The material and coating of the milling cutter is to determine the basis of its life. For insulating materials, it is recommended to choose high hardness, high wear resistance cutting tool materials, such as cemented carbide, polycrystalline diamond (PCD) or diamond coated tools. These materials have excellent cutting performance and wear resistance, and are particularly suitable for processing difficult-to-machine materials such as glass fiber and resin matrix composites. In addition, high-quality coatings such as diamond coating can reduce the coefficient of friction and improve heat resistance, further slowing down cutting tool wear.

Second, optimize cutting parameters

Cutting parameters directly affect the force and temperature of the cutting tool. When processing insulating materials, should follow the “high speed, low feed, small depth of cut” principle, in order to reduce the cutting force and heat accumulation. Excessive feed or depth of cut will lead to overloading of the cutting tool, accelerating wear and even chipping. According to the characteristics of different materials, reasonable setting of spindle speed, feed rate and depth of cut, is to extend the life of cutting tool is an important measure.

Third, strengthen the cooling and lubrication

Insulating materials have poor thermal conductivity, processing is easy to produce high temperatures, exacerbating cutting tool wear. Therefore, effective cooling must be used. Air cooling or micro lubrication (MQL) is a commonly used means to effectively reduce the cutting temperature and reduce thermal damage. At the same time, avoid the use of excessive coolant, so as not to contaminate the material or affect the machining accuracy.

Fourth, regular maintenance and proper use

Routine maintenance of the cutting tool is equally important. The cutting tool should be checked for wear after each use, and the badly worn tool should be replaced in a timely manner. Keep the cutting tool clean to avoid resin or dust adhesion. In addition, correctly install the cutting tool to ensure that the clamping is firm, accurate tool alignment, to avoid abnormal wear caused by swing or vibration.

Fifth, improve the machining process and clamping

The use of smooth milling, optimize the design of fixtures, the use of vacuum adsorption and other clamping methods can reduce machining vibration, improve the uniformity of cutting tool force, thereby extending the service life. Process optimization can often significantly reduce the abnormal loss of cutting tool.

Through the above introduction, it can be seen that extending the life of milling cutters for insulating materials is a comprehensive project involving multiple aspects such as cutting tool selection, parameter optimization, cooling and lubrication, maintenance management and process improvement. Through scientific and reasonable methods, not only can reduce the frequency of cutting tool replacement and processing costs, but also improve processing efficiency and product quality.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.