Email Us

Do You Know The Types And Uses Of Stone Carving Milling Cutter?

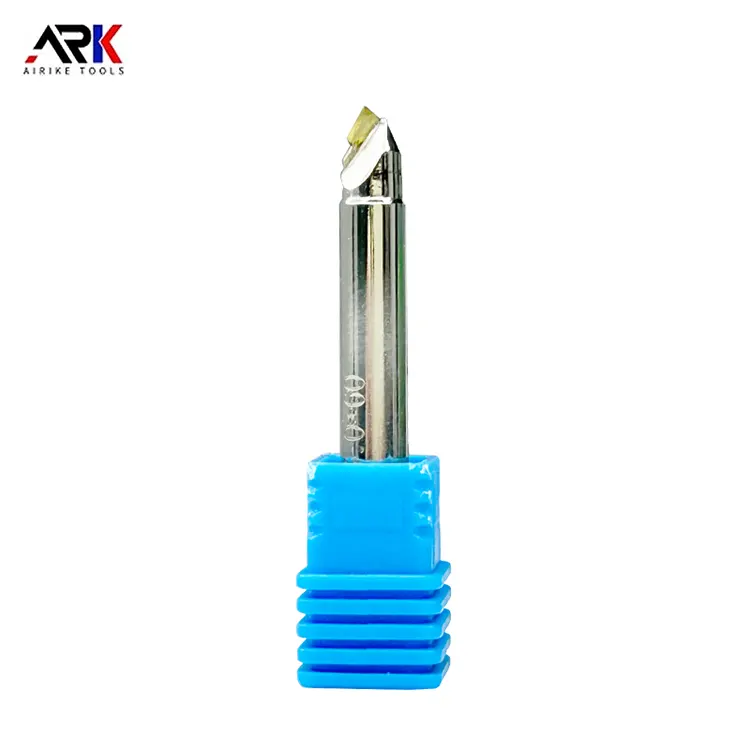

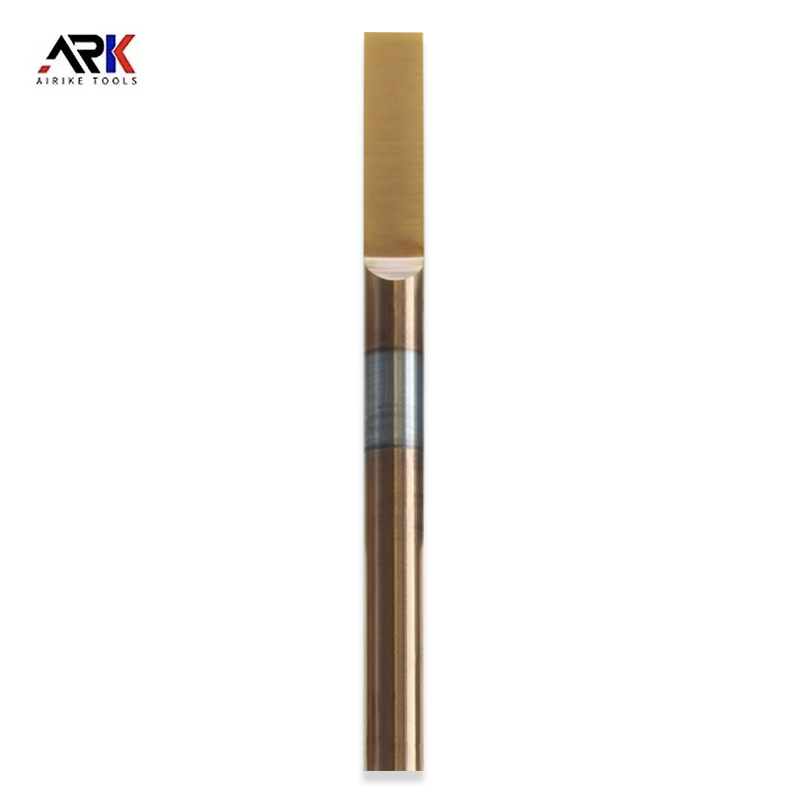

There are three main types of Stone Carving Milling Cutter. Diamond cutters are hard and strong, especially suitable for carving hard stones. During use, coolant can be used to reduce the temperature of diamond cutters, thereby extending their service life. PCD cutters are made of artificial nanocrystalline diamonds, which have strong hardness and wear resistance. They can accurately and efficiently carve stone patterns and are not easy to wear. During the use of PCD cutters, it is necessary to control the processing speed and avoid rapid rotation or high-speed vibration to avoid damage to the cutter. High-speed steel cutters are mainly used for carving medium-hard stones and have good toughness and cutting performance. During use, it is necessary to control the processing depth and feed speed to avoid overheating or excessive wear of the cutter.

So how to choose and use the cutter?

The selection of engraving cutters needs to be made according to the specific stone material and engraving requirements. When choosing engraving cutters, you first need to consider the engraving material, such as marble, granite, etc., and then combine the characteristics of the stone such as hardness and toughness to choose the appropriate cutter.

Different carving patterns and effects need to be achieved, and different Stone Carving Milling Cutter should be selected. For example, if you need to cut a shallow pattern, you can choose a high-speed steel tool; if you need to cut a pattern with high precision and delicate effect, you can choose a PCD tool.

When using the tool, you need to clean the tool surface and handle regularly, and replace the tool with greater wear in time to ensure the cutting effect and carving accuracy.

When using the Stone Carving Milling Cutter, the operator needs to reasonably adjust the processing parameters according to the characteristics of the tool and material to avoid excessive processing or cutting too deep to cause tool wear or damage. During cutting, coolant should be used to ensure that the Stone Carving Milling Cutter does not overheat to extend its service life. When replacing the tool, pay attention to the matching of the tool type and size, and replace it according to the requirements of the stone engraving machine.

The selection and use of Stone Carving Milling Cutter tools are related to the engraving effect and cutting quality. Reasonable selection of tools and proper maintenance and replacement can improve engraving efficiency and quality, which plays an important role in the development of the stone engraving industry.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.