Email Us

Is a spiral or straight flute woodworking milling cutter better for edge trimming?

In woodworking edge trimming operations, spiral-fluted and straight-fluted milling cutters are common choices. However, differences exist between them in cutting performance, material compatibility, and operational difficulty, leaving many practitioners or buyers uncertain about selection. The key lies in matching wood type, trimming requirements, and machining equipment. Let Zhongyeda guide you through the process.

Advantages of Spiral-Fluted Woodworking Milling Cutters for Edge Trimming

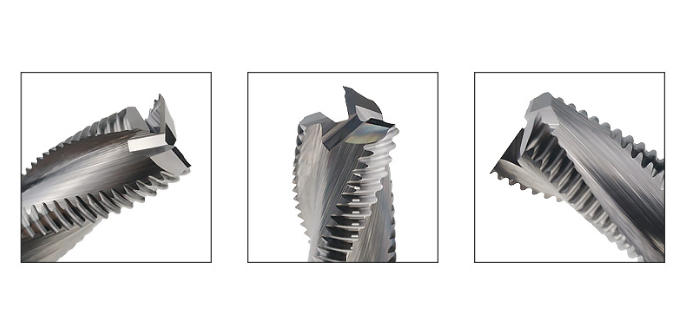

The spiral-fluted cutter features helically arranged cutting edges. During machining, it makes smoother contact with the wood, distributing force evenly and minimizing vibration. This effectively reduces chipping and tearing, making it particularly suitable for hardwoods, high-density boards, and other materials with dense textures or complex grain patterns. Its efficient chip evacuation channels prevent sawdust buildup that could compromise machining accuracy. The finished edge exhibits a high surface finish, reducing the need for subsequent sanding.

Clearly, this type of woodworking milling cutter excels in applications demanding high edge quality, such as exposed furniture edges or decorative panel trimming.

Key Trimming Characteristics of Straight-Edge Woodworking Milling Cutters

Straight-edge milling cutters feature cutting edges perpendicular to the shaft, enabling fast cutting speeds with minimal feed resistance. Their low operational threshold makes them ideal for trimming soft woods like pine or spruce. Their simple construction and affordable cost make them easy to maintain—blades can be reground after wear, keeping upkeep expenses low.

However, straight-edge cutters generate significant impact force during cutting, making them prone to chipping on hardwoods or cross-grained timber. They are better suited for basic trimming tasks with lower edge precision requirements, such as processing concealed panels or temporary fixtures.

How to select the right type? Key reference factors include

Prioritize wood hardness when selecting a woodworking milling cutter. For hardwoods or high-density materials, choose spiral flutes; for softwoods or standard panels, straight flutes are suitable.

If the trimmed edge will be exposed and a refined finish is desired, spiral flutes are the superior choice. If processing efficiency and cost control are priorities, straight flutes offer greater advantages. Simultaneously, match the cutter to the processing equipment: straight-flute cutters are easier to control with handheld electric woodworking mills, while spiral-flute cutters deliver higher precision advantages when paired with CNC woodworking machines.

In summary, there is no absolute superiority in selecting woodworking milling cutters for trimming operations. The core principle is aligning with material characteristics and processing requirements. Opt for spiral-flute cutters for high-quality edges, and choose straight-flute cutters for efficiency and cost considerations. Combining practical scenarios will lead to the appropriate selection.

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

- How to Choose Between PCD and MCD Tools?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.