Email Us

How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

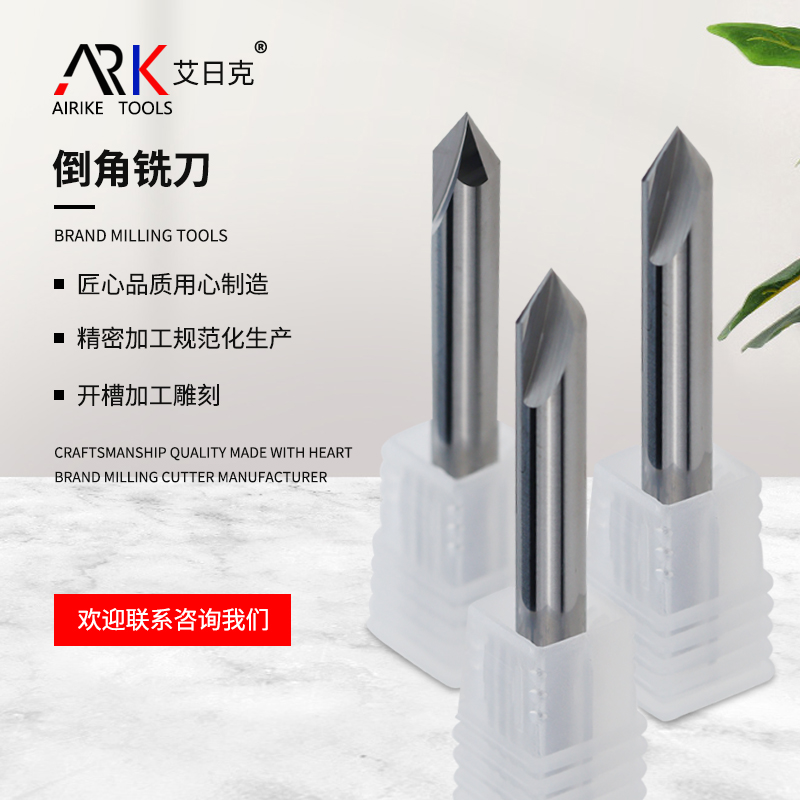

Chamfering is a fundamental process in metalworking and mold manufacturing, removing burrs from parts and improving assembly smoothness. A well-matched chamfering tool boosts processing efficiency and ensures more uniform chamfering results. However, the market offers a wide array of chamfering tool brands—from international to domestic—with significant variations in price and performance. To select a brand that meets your specific needs, follow the step-by-step screening method outlined below by Zhongye Da.

Define Your Processing Requirements

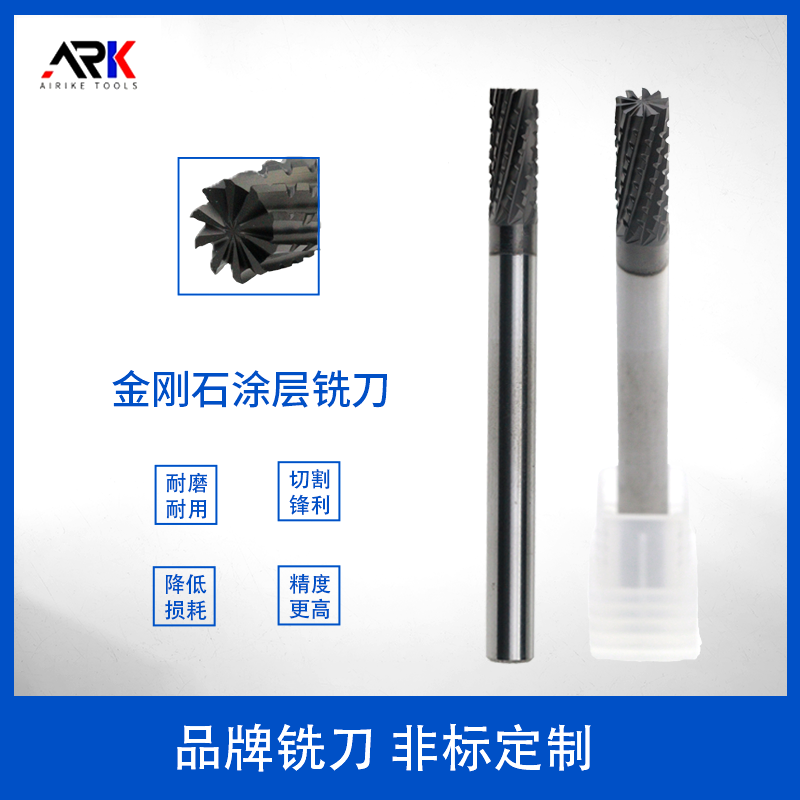

Before selecting a brand, clarify your specific processing scenarios. Different materials demand distinct tooling characteristics: cost-effective brands suffice for common carbon steel or aluminum alloys, while machining difficult-to-cut materials like stainless steel or titanium alloys requires prioritizing brands with superior substrate materials and coating technologies.

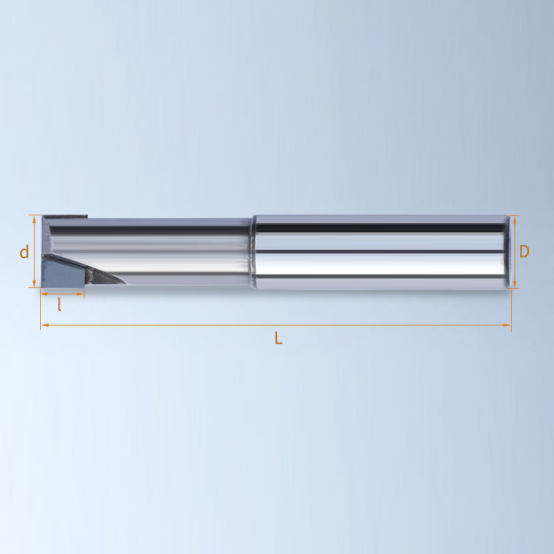

Processing volume and precision requirements must also be considered. For small-batch trimming operations, premium brands aren't necessary, while large-scale automated production prioritizes tool life and stability. Machinery type influences selection: manual chamfering emphasizes cutting feel, whereas CNC machining demands dynamic balance and geometric precision.

Evaluate Brand Capabilities

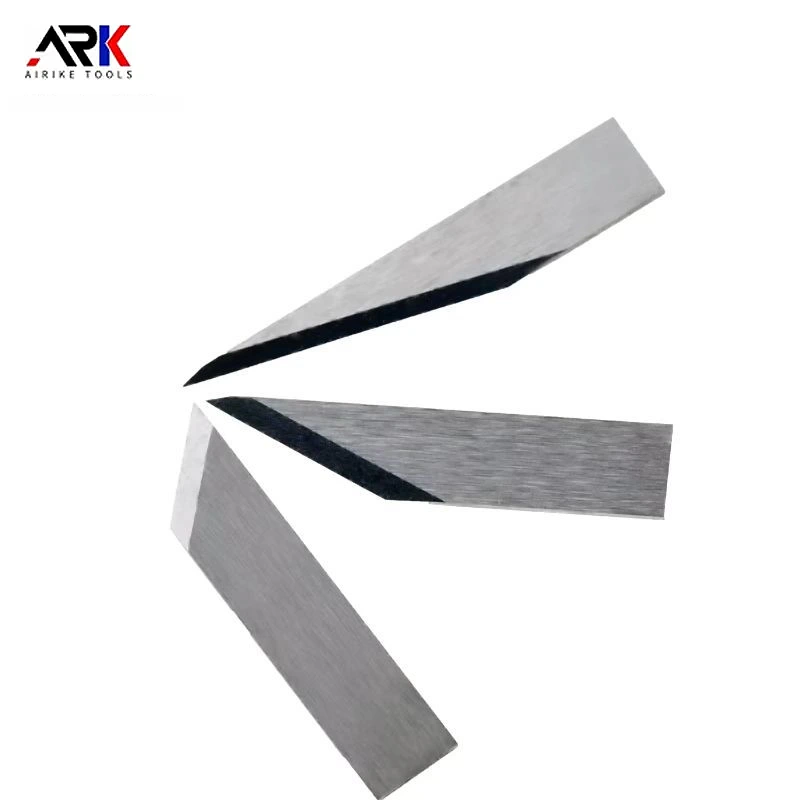

A brand's R&D capability is fundamental. Established brands design tool flute geometries tailored to specific materials and apply advanced coating technologies to enhance durability. Consistent quality is equally critical; brands with stringent quality control ensure minimal performance variation in shipped tools, reducing quality issues during machining.

Additionally, technical support and supply chain reliability should not be overlooked. Brands offering selection guidance and timely delivery provide greater operational convenience.

Balancing Cost and Benefit

Selecting a brand requires evaluating total cost, not just unit price. Low-cost tools may wear quickly, necessitating frequent replacements that disrupt production schedules. While high-performance tools have a higher purchase price, their extended lifespan and superior stability can result in lower per-part costs when amortized.

Implementing a tiered procurement strategy—selecting high-performance brands for critical processes and cost-effective brands for auxiliary processes—can optimize overall costs.

In summary, the key to selecting chamfering tool brands lies in aligning with your specific needs while comprehensively evaluating brand strength and cost-benefit ratios.

By following this decision-making approach, you can navigate the complex market to find the ideal partner that truly creates value and enables efficient production.

-

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.