Email Us

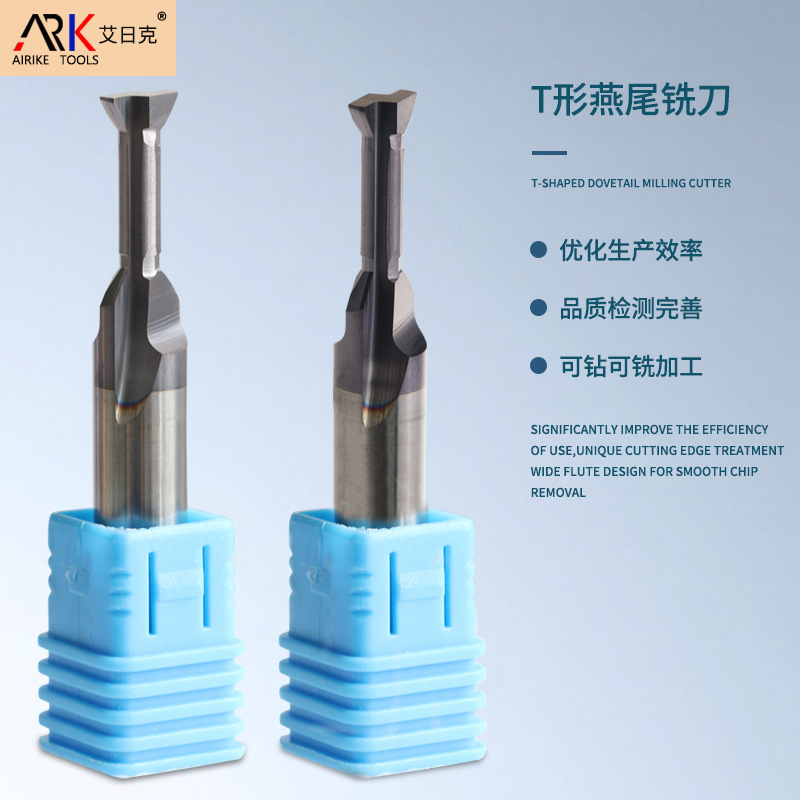

Standard features of T-type knives

T-type knives are a commonly used cutting tool for milling metals and other materials. They are T-shaped and have some standard features. The following is a detailed introduction by the editor of Zhongyeda.

Standard features of T-type knives:

1. Shank shape: The shank of a T-type knife is T-shaped, with a longitudinal raised shank in the middle and parallel transverse shanks on both sides. This shape is conducive to the fixation and stability of the tool.

2. Tip shape: The tip of a T-type knife is usually flat or chamfered, and is used to cut the surface of the workpiece.

3. Blade material: The blade of a T-type knife is usually made of high-speed steel (HSS) or carbide. High-speed steel blades are suitable for general milling work, while carbide blades are suitable for high-hardness materials and high-speed cutting.

4. Blade installation method: The blade of a T-type knife can be fixed to the shank by a thread or a clamping device. The threaded fixing method is suitable for larger blades, and the clamping device is suitable for smaller blades.

5. Number of blade edges: T-type cutters usually have single-edge and multi-edge blades. Single-edge blades are suitable for general milling work, while multi-edge blades are suitable for high-efficiency cutting.

6. Blade coating: In order to improve the wear resistance and cutting performance of the tool, some T-type milling cutters will have their blade surfaces coated, such as coated titanium carbide (TiCN), coated titanium nitride (TiN), etc.

The above standard features of T-type cutters are shared here. In short, the standard features of T-type cutters include T-shaped shank, flat head or chamfered tip, high-speed steel or carbide blade, threaded or clamping device installation method, single-edge or multi-edge blade and coating treatment, etc.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.