Email Us

What are the characteristics and uses of graphite milling cutter?

As a non-metallic material with excellent electrical conductivity, high temperature resistance and self-lubrication, graphite is widely used in mold making, electronic industry, aerospace and other fields. And graphite milling cutter as a cutting tool specially used for processing graphite materials, with its unique structure and performance, become an indispensable and important tool in the field of graphite processing. So how much do you know about the characteristics and uses of graphite milling cutter? The following follow zhongye da editor to take a look!

First, the characteristics of graphite milling cutter

1, high hardness and wear resistance

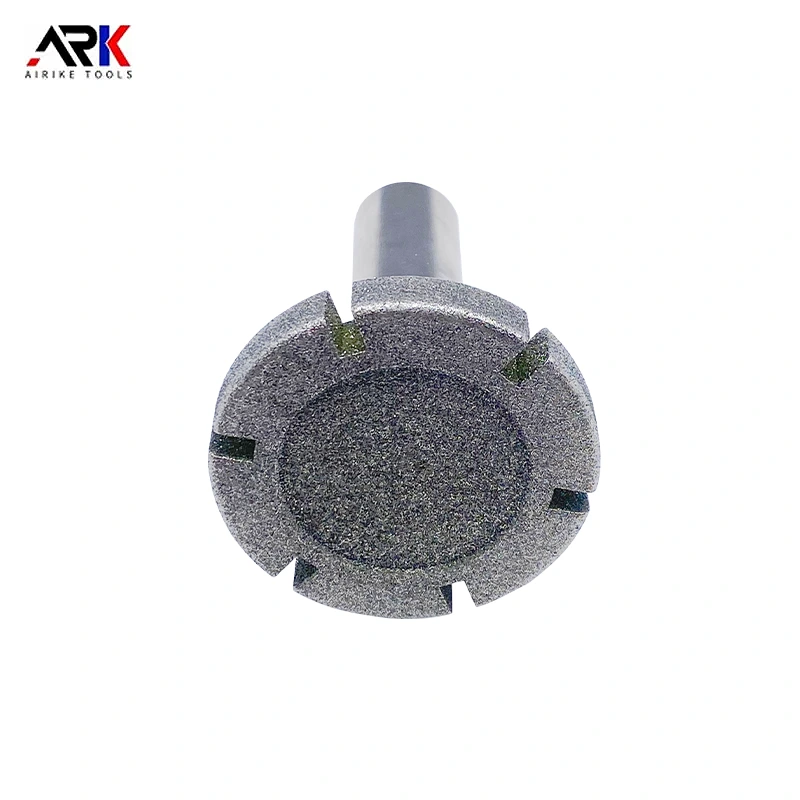

Although the graphite material is soft, it contains a large number of hard particles inside, which is extremely abrasive to the cutting tool. Therefore, graphite milling cutters are usually made of high hardness materials such as ultra-fine grain carbide, polycrystalline diamond (PCD) or ceramics, which have strong wear resistance and can maintain a sharp cutting edge for a long time.

2、Special geometric design

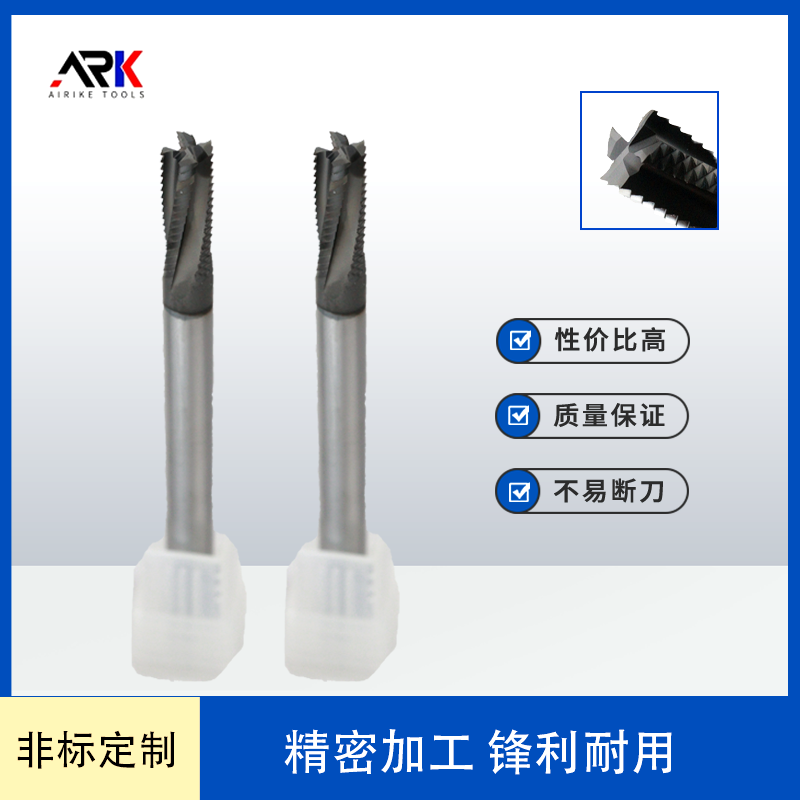

The edge design of graphite milling cutter usually adopts large helix angle, multi-flute structure, in order to improve the cutting efficiency and chip removal ability. At the same time, in order to reduce the chipping phenomenon in graphite processing, the cutting tool's edge is finely polished or chamfered to reduce the stress concentration in the cutting process.

3、Excellent chip removal performance

Graphite machining process will produce a large number of fine dust, easy to block the cutting tool or affect the machining accuracy. Graphite milling cutter can effectively remove chips and reduce cutting temperature to prolong cutting tool life by optimizing the structure of chip holding groove and adopting internal cooling design.

4、Anti-adhesion and self-lubrication

Graphite itself has a certain degree of self-lubrication, but in the high-speed cutting process may still occur sticky knife phenomenon. The surface of graphite milling cutter is usually treated with special coating (such as diamond coating, diamond-like coating, etc.), which can further reduce adhesion and improve the processing surface quality.

Second, the use of graphite milling cutter

1、Electrode processing

In electric discharge machining (EDM), graphite electrodes are widely used because of their good conductivity, high processing efficiency, light weight and other advantages. Graphite milling cutter is used to efficiently process graphite electrodes with complex shapes, such as cavity electrode, slender electrode, etc., which can meet the requirements of high precision and high surface quality.

2、Mold manufacturing

Graphite material is often used in the mold industry to manufacture high temperature molds, glass molds, casting molds and so on. Graphite milling cutter can process complex mold cavities and fine structure to ensure the dimensional accuracy and surface finish of the mold.

3、Electronics and semiconductor industry

Graphite is used in the electronics industry to manufacture heat sinks, battery electrodes, semiconductor substrates and other components. Graphite milling cutter can efficiently process these high-precision parts, to meet the electronics industry on the material properties and processing accuracy of the strict requirements.

4、Aerospace and new energy

In the field of aerospace and new energy, graphite materials are widely used in composite materials, fuel cells and other components due to its lightweight, high strength, high temperature resistance and other characteristics. Graphite milling cutter can process these high-performance materials to meet the requirements of extreme working conditions.

In summary, graphite milling cutter has become an important tool in the field of graphite processing by virtue of its high hardness, wear resistance, excellent chip removal performance and special geometric structure design. In the field of electrode machining, mold manufacturing, electronics and semiconductor, aerospace and other fields, graphite milling cutter plays an irreplaceable role.

- The same milling cutter, the market phenomenon of milling cutter price difference

- Korean customers visited our company to discuss a new chapter of milling cutter cooperation!

- Using the wrong cutting fluid is like throwing away money on milling cutters?

- Zongyeda Explains - Clockwise or Counterclockwise Rotation for Woodworking Milling Cutters?

- Zhongyeda - What's the Difference Between Chamfering Tools and Centering Drills?

- How to Scientifically Determine the Milling Depth for Woodworking Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.