Email Us

What is the difference between welded milling cutter and ordinary milling cutter?

In the field of industrial processing, welded milling cutter and ordinary milling cutter are two common cutting tools, welded milling cutter is characterized by the cutter head and cutter body are connected by welding, this design makes it possible to replace the cutter head after the wear of the insert, which prolongs the service life of the cutting tool, and at the same time reduces the cost of use. The ordinary milling cutter is mostly integral or indexable structure, the blade and cutter body is usually molded or fixed by mechanical clamping, although the structure is simple, but often need to replace the whole after the blade wear, the economy is relatively low. So do you know what is the difference between welded milling cutter and ordinary milling cutter? The following follow zhongye da editorial to take a look!

The difference between welded milling cutter and ordinary milling cutter is as follows:

Structural characteristics: different connection methods

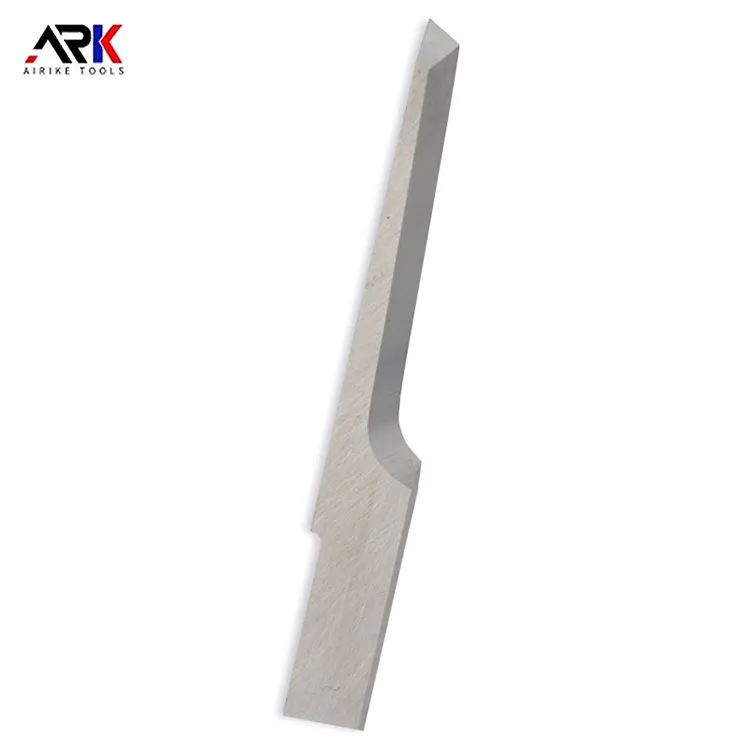

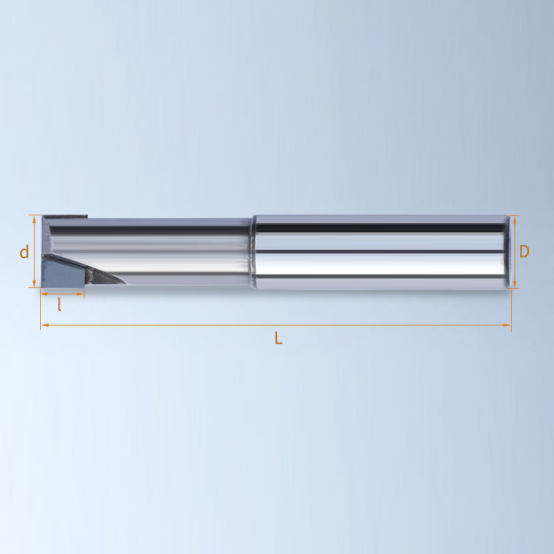

The most important feature of the welded milling cutter is that its cutter head and cutter body are connected by welding to form a whole structure. This design makes the welded milling cutter in the blade wear, you can replace the cutter head without having to replace the entire cutting tool, thus extending the service life of the tool. In contrast, the ordinary milling cutter is mostly integral or indexable structure, the blade and the cutter body are usually molded or fixed by mechanical clamping. Although this type of structure is simple, the inserts usually need to be replaced as a whole when they wear out, resulting in a higher cost of ownership.

Manufacturing Costs: Economy and Flexibility

The relatively low manufacturing costs of welded milling cutters are a major advantage. As the cutter head and cutter body are manufactured separately, welded milling cutters can be customized according to specific needs, avoiding unnecessary waste, especially suitable for small batch, multi-variety processing needs. While ordinary milling cutters, especially integral milling cutters, are more expensive to manufacture, their stability and consistency are more advantageous in high-volume production.

Scope of application: differences in machining scenarios

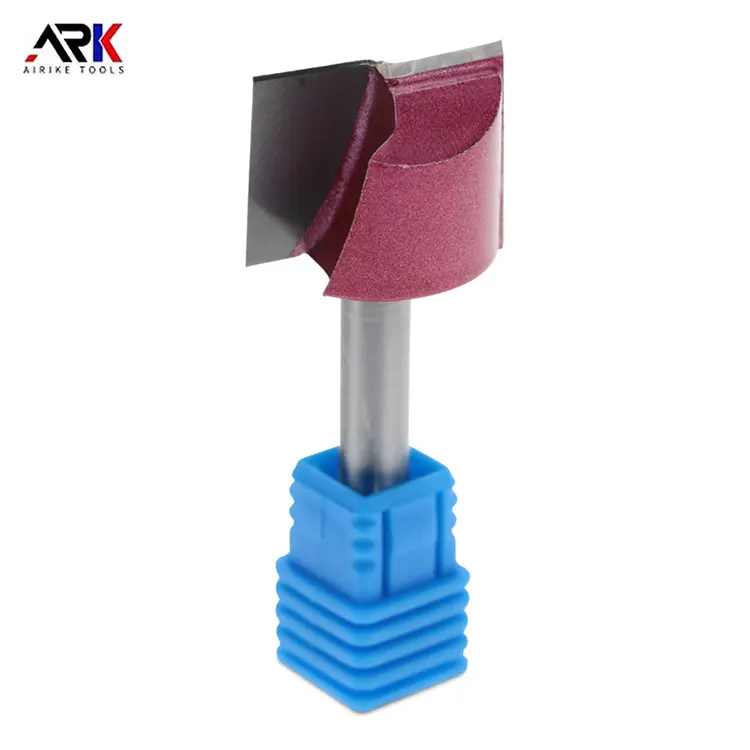

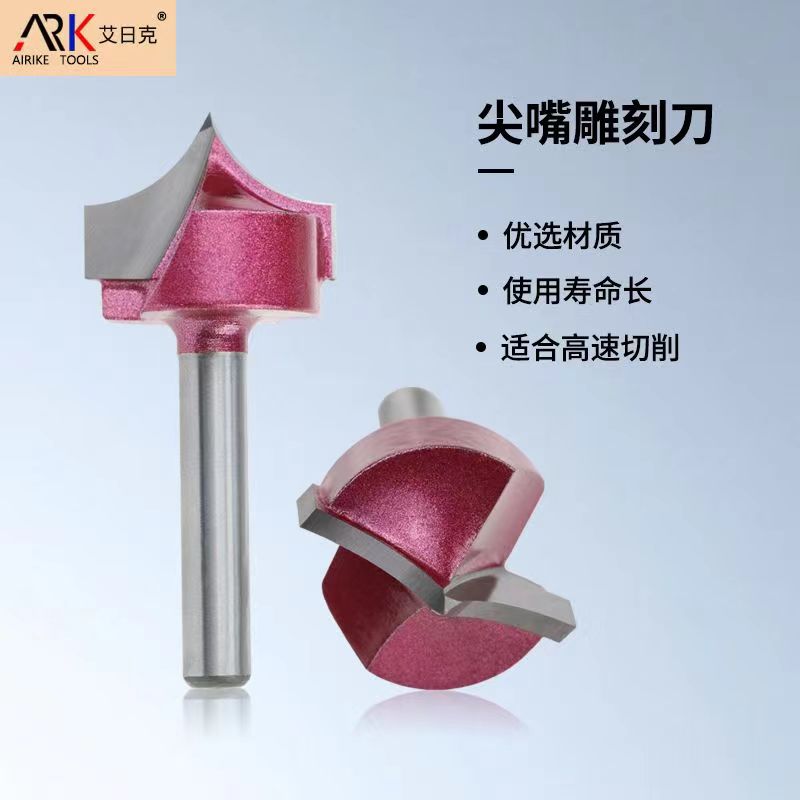

Welding cutters are widely used in mold manufacturing, complex surface processing and other fields. In the mold manufacturing industry, welded milling cutters are often used to process cavities, cores and other key components, which can ensure the machining accuracy and surface quality. In addition, welded milling cutters are excellent in machining high hardness materials, and their welded structure can withstand large cutting forces. Ordinary milling cutters are more suitable for regular operations such as flat surface machining and groove machining, especially in scenarios requiring high efficiency and mass production, their advantages are more obvious.

Precautions for use: points for operation and maintenance

When using welded milling cutters, special attention should be paid to the strength and wear resistance of the welded joints. Since the welded part may become a weak point of the cutting tool, excessive cutting force and impact should be avoided during machining to prevent the cutter head from falling off. In addition, the replacement of welded milling cutters requires specialized welding equipment and technology, which requires high operator skills. The use of ordinary milling cutter is relatively simple, but in high-speed cutting need to pay attention to the balance and stability of the cutting tool, in order to avoid vibration affect the processing quality.

Overall, welding milling cutter and ordinary milling cutter have their own advantages and disadvantages, the choice should be based on specific processing needs, material characteristics and cost budget comprehensive consideration. Welding cutter with its economy and flexibility in small quantities, complex processing advantages, while the ordinary milling cutter in large quantities, high-efficiency machining performance is more outstanding. Through the rational selection and use of these two types of milling cutter, you can effectively improve machining efficiency, reduce production costs, and provide strong support for industrial manufacturing.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.