Excellent Quality

The company has always adhered to the principle of customer first and quality first, and has established a strict quality management system since its inception.

Preferred Raw Material

We are extremely careful about the materials of each product, and we have a careful and systematic quality assurance system from the introduction of raw materials to the beginning of the finished product.

Continuous Innovation

For a long time, the company according to the market demand, continuous innovation, actively develop new products, the pursuit of quality, the establishment of a unified, perfect service system.

Perfect Service

Customer satisfaction is the permanent goal of modern business organization activities, with "honesty, trust, precision, diligent" for the purpose of society, to provide fast, safe, heavy faith, promise of the full range of services

About Us

Shenzhen Zhongyeda Precision Technology Co., Ltd.

You can rest assured to buy engraving machine milling cutter, woodworking milling cutter, metal cutting milling cutter from our factory and we will offer you the best after-sale service and timely delivery. Zhongyeda engraving machine milling cutter, woodworking milling cutter, metal cutting milling cutter have a well-earned reputation for functionality and safety.

Featured Products

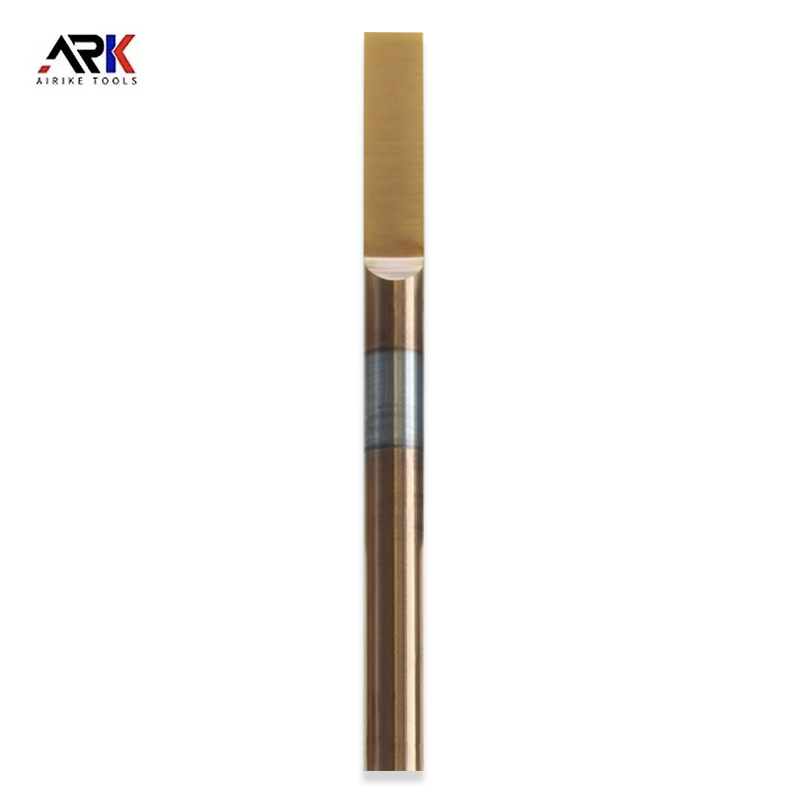

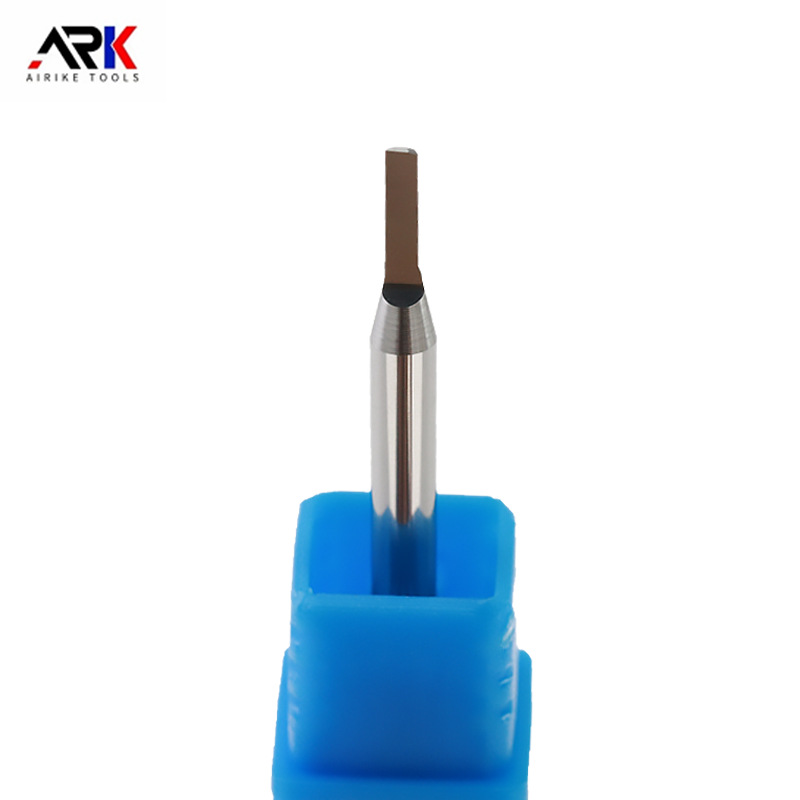

Round Nose Milling Cutter

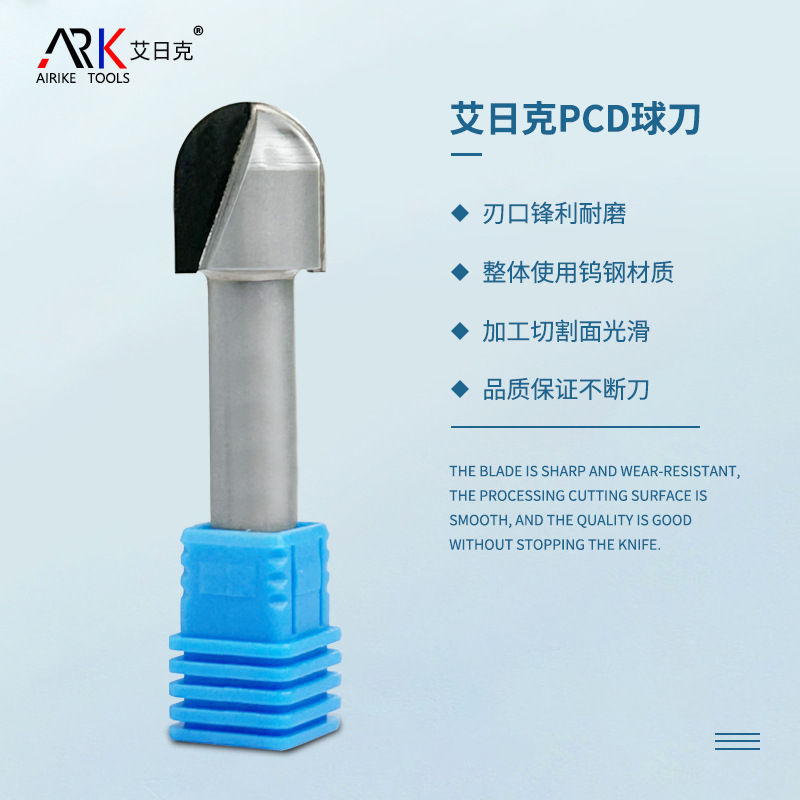

+Ball-end Milling Cutter

+Flat-bottomed knife

+Left-Handed Combination Cutters

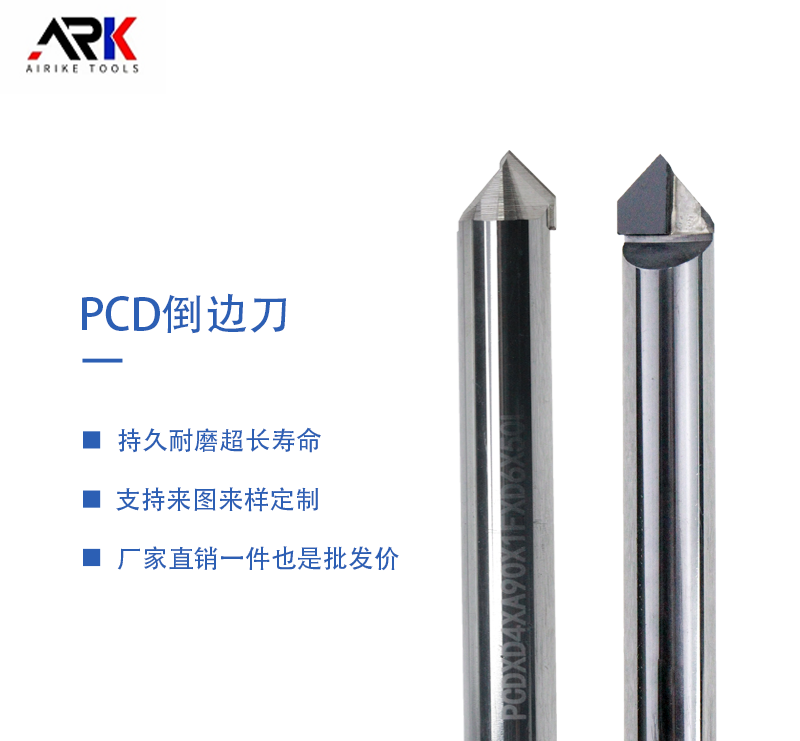

+PCD Chamfering Cutter

+Triple Edge Wood Splitting Knife

+2.0mm corn milling cutter

+10° Taper Ball Cutter

+Guide plate milling cutter

+TCT double-flute left-handed milling cutter

+Welded milling cutter

+Tungsten steel half milling cutter

+Send Inquiry

Address

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen