Email Us

What are the types of milling cutters?

Milling cutters are rotary tools with one or more teeth used for milling. When working, each tooth cuts off the workpiece's excess in turn and intermittently. They are mainly used to process planes, steps, grooves, forming surfaces and cut off workpieces on milling machines. So what are the types of milling cutters? The following is a detailed introduction to this issue.

Milling cutters are generally divided into:

1. Flat-head milling cutters, for rough milling, removal of a large number of blanks, small-area horizontal planes or contours.

2. Ball-end milling cutters, for semi-finishing and finishing milling of curved surfaces; small ball-end milling cutters can finish milling small chamfers of steep surfaces/straight walls and irregular contour surfaces.

3. Flat-head milling cutters with chamfers can be used for rough milling to remove a large number of blanks, and can also finish milling small chamfers of fine flat surfaces (relative to steep surfaces).

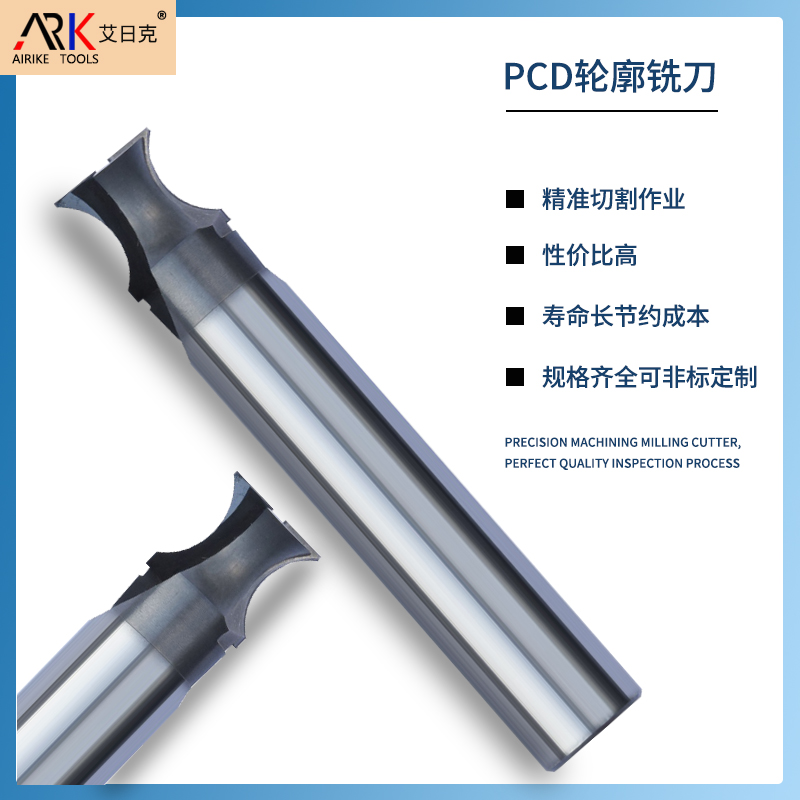

4. Forming milling cutters, including chamfering cutters, T-shaped milling cutters or drum cutters, tooth-type cutters, and internal R cutters.

5. Chamfering cutter, the shape of the chamfering cutter is the same as the chamfering shape, and it is divided into milling round chamfering and oblique chamfering milling cutter.

6. T-type cutter, which can mill T-slots.

7. Tooth-shaped cutter, which can mill various tooth shapes, such as gears.

8. Roughing cutter, a roughing cutter designed for cutting aluminum-copper alloys, can be processed quickly.

The above is about the general types of milling cutters. I hope this article will be helpful to everyone. If you have other questions about chamfering cutters, you can follow Zhongyeda or leave a message to the editor. We look forward to discussing with you!

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

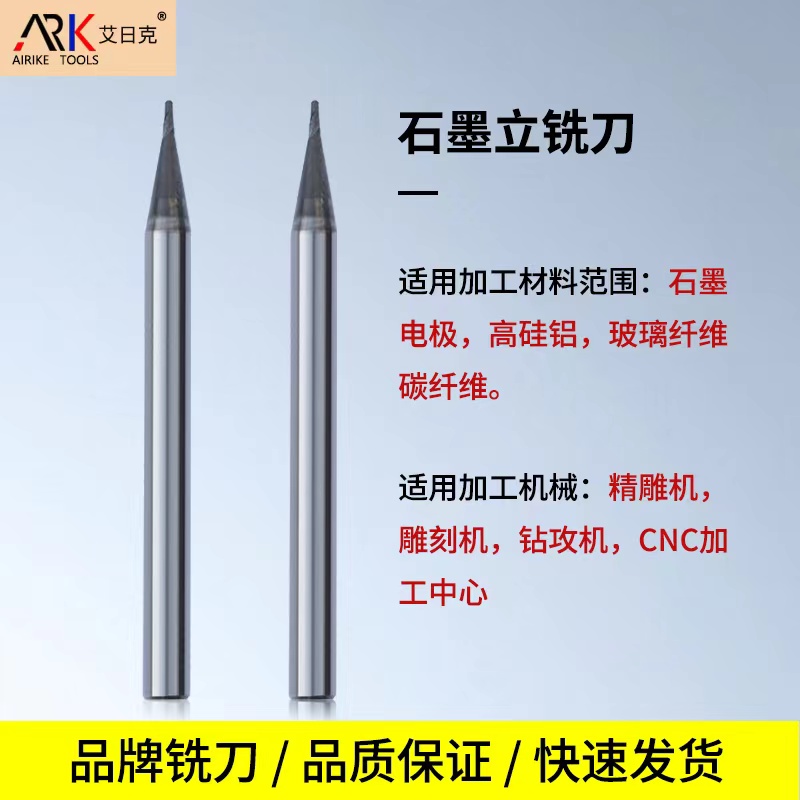

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.