Email Us

What Makes Diamond Milling Cutters the Smart Choice for Precision Machining?

In the competitive world of precision engineering and advanced machining, tool selection directly determines production efficiency, surface finish quality, and tool life. Among the most sought-after tools today are Diamond Milling Cutters, known for their extreme hardness, wear resistance, and ability to handle challenging materials such as composites, aluminum alloys, and non-ferrous metals.

-

How do Diamond Milling Cutters achieve unmatched precision and durability?

-

Why should manufacturers consider PCD Straight Edge Cutters for demanding applications?

-

What makes PCD Ball Cutters indispensable in high-precision 3D profiling?

-

How can choosing the right supplier like Zhongyeda ensure lasting performance and support?

Through in-depth explanations, technical parameters, professional comparison tables, and practical insights, this guide will help you understand the true value of Diamond Milling Cutters and their role in modern machining.

1. How Do Diamond Milling Cutters Achieve Precision and Extended Tool Life?

Diamond milling cutters are engineered with Polycrystalline Diamond (PCD) cutting edges, which rank among the hardest known materials. Compared to conventional carbide tools, diamond cutters deliver exceptional wear resistance, thermal stability, and cutting accuracy, making them indispensable in industries such as aerospace, automotive, electronics, and mold manufacturing.

Key Performance Advantages

-

Extreme Hardness: PCD edges resist abrasion, maintaining sharpness for much longer.

-

Low Friction Cutting: Reduces heat buildup, ensuring stable cutting performance.

-

Superior Surface Finish: Delivers mirror-like finishes with reduced need for secondary polishing.

-

Longer Tool Life: Up to 10–20 times longer lifespan than carbide alternatives.

-

Material Versatility: Ideal for machining aluminum, composites, ceramics, and non-ferrous alloys.

Technical Parameters of Diamond Milling Cutters

| Parameter | Specification Range | Benefits |

|---|---|---|

| Cutting Edge Material | Polycrystalline Diamond (PCD) | Superior hardness and wear resistance |

| Cutter Diameter | Ø 3 mm – Ø 40 mm | Flexible options for fine to heavy machining |

| Shank Diameter | 4 mm – 25 mm | Compatible with different machine tool setups |

| Cutting Edge Geometry | Straight / Ball / Custom Profiles | Tailored for flat surfaces or 3D contour machining |

| Cutting Speed | 800 – 3000 m/min | High productivity with minimal thermal deformation |

| Workpiece Materials | Aluminum, CFRP, Copper, Ceramics | Versatile machining for lightweight and high-strength materials |

| Tool Life Expectancy | 10–20x longer than carbide tools | Reduced downtime and lower overall tooling costs |

By integrating diamond milling cutters into production lines, companies benefit from higher productivity, cost savings, and superior machining accuracy.

2. Why Choose PCD Straight Edge Cutters for Flat Surface Excellence?

For applications where flat surface machining, edge trimming, and slotting are essential, the PCD Straight Edge Cutter is the go-to solution. Designed with precision-ground diamond cutting edges, these tools ensure sharp, consistent performance on tough materials.

Advantages of PCD Straight Edge Cutters

-

Sharp Cutting Profile: Ensures high-quality flat finishes without burrs.

-

Ideal for Composites and Aluminum: Handles delamination-prone and sticky materials efficiently.

-

Stable Edge Geometry: Reduces vibration, enabling smoother cuts at higher feed rates.

-

Extended Durability: Maintains performance across long production runs.

Technical Parameters of PCD Straight Edge Cutter

| Parameter | Specification Range | Application Benefit |

|---|---|---|

| Cutter Type | Straight Edge | Precision machining of flat surfaces and slots |

| Diameter Range | Ø 4 mm – Ø 30 mm | Flexibility for fine finishing and rough cutting |

| Cutting Edge Length | 5 mm – 50 mm | Suitable for shallow and deep slotting |

| Workpiece Suitability | Aluminum, CFRP, Copper | Widely used in aerospace and automotive industries |

| Edge Accuracy | ±0.002 mm | High repeatability for precision components |

The PCD Straight Edge Cutter is especially valuable in electronics casing, automotive body parts, and aerospace components, where flatness and dimensional accuracy are critical.

3. What Makes PCD Ball Cutters Essential in 3D Profiling?

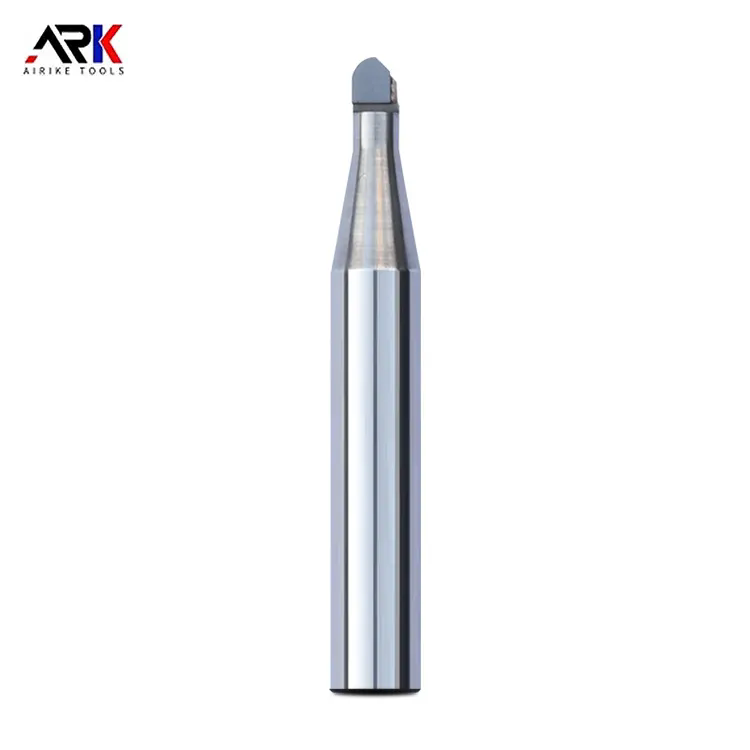

In advanced mold manufacturing and 3D component shaping, PCD Ball Cutters play an irreplaceable role. With a ball-shaped cutting geometry, these tools can machine complex contours, cavities, and freeform surfaces with high precision.

Advantages of PCD Ball Cutters

-

Perfect for 3D Contouring: Smoothly machines curved profiles and intricate geometries.

-

Mirror-Like Finish: Achieves ultra-smooth surfaces in molds and dies.

-

Reduced Polishing Time: Minimizes manual finishing needs, lowering overall production costs.

-

Long-Lasting Accuracy: Diamond edges maintain their radius and sharpness over extended use.

Technical Parameters of PCD Ball Cutter

| Parameter | Specification Range | Application Benefit |

|---|---|---|

| Cutter Type | Ball Nose | 3D profiling and contour machining |

| Diameter Range | Ø 2 mm – Ø 20 mm | Suitable for small detail work and larger contours |

| Cutting Edge Radius | 1 mm – 10 mm | Customizable for varying depth of curvature |

| Workpiece Suitability | Graphite, Aluminum, CFRP | Widely used in mold, aerospace, and electronics sectors |

| Tool Life Expectancy | Up to 15x longer than carbide | Reduces re-sharpening downtime and boosts productivity |

The PCD Ball Cutter is essential for mold making, turbine blade machining, and 3D cavity finishing, where surface smoothness and accuracy directly impact product quality.

4. How Can Choosing Zhongyeda Ensure Consistent Quality and Support?

Beyond technical specifications, the choice of supplier determines the long-term success of machining operations. Zhongyeda has established itself as a trusted brand in the field of Diamond Milling Cutters, delivering not only tools but also engineering expertise and after-sales support.

Why Zhongyeda?

-

Comprehensive Product Range: From PCD straight edge cutters to PCD ball cutters, providing complete tooling solutions.

-

Stringent Quality Control: Each cutter undergoes precision testing for dimensional accuracy and edge integrity.

-

Tailored Solutions: Ability to design custom geometries for specialized applications.

-

Global Support: Dedicated customer service and technical guidance available worldwide.

By selecting Zhongyeda Diamond Milling Cutters, manufacturers gain consistency, reliability, and value-added engineering support, ensuring smoother production cycles and improved cost-efficiency.

Frequently Asked Questions (FAQ) about Diamond Milling Cutters

Q1: What materials can Diamond Milling Cutters machine effectively?

A1: They are ideal for non-ferrous metals like aluminum and copper, composites such as CFRP, graphite, and ceramics, delivering superior finishes and long tool life.

Q2: Why do Diamond Milling Cutters last longer than carbide tools?

A2: Their cutting edges are made from polycrystalline diamond, which is significantly harder and more wear-resistant than carbide, allowing up to 20x longer performance.

Q3: How do I choose between a PCD Straight Edge Cutter and a PCD Ball Cutter?

A3: Use a Straight Edge Cutter for flat surface machining and slotting, and a Ball Cutter for 3D profiling, mold cavities, or curved surfaces requiring high precision.

Partner with Zhongyeda for Lasting Success

The world of precision machining demands tools that can balance durability, accuracy, and efficiency. Whether it is the PCD Straight Edge Cutter for flat and stable machining or the PCD Ball Cutter for high-precision 3D profiling, Diamond Milling Cutters remain the benchmark of excellence.

With a proven track record in delivering high-performance tooling solutions, Zhongyeda empowers manufacturers to achieve faster production cycles, reduced tool costs, and higher surface quality.

For inquiries, custom solutions, or to explore our full product catalog, we invite you to contact us today and experience the cutting-edge performance of Zhongyeda Diamond Milling Cutters.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.